[Powerplant | Overview | Rolls Royce | Pratt & Whitney | General Electric]

OVERVIEW

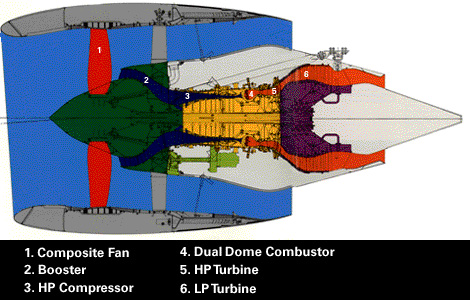

MAJOR COMPONENTS OF ADVANCED TURBOFAN ENGINES

The Boeing 777 is equipped with some of the world's largest aircraft engines in history. These engines, high-bypass, turbofans, developed specifically for the 777, are the most reliable, most powerful, and most fuel efficient. Such engines were necessitated by the 777's design goals of carrying the same payload over the long-range routes previously traversed by earlier four-engined 747s, yet burning less fuel, polluting less, generating less noise, and suffer less failures. All these characteristics help the 777 to be the most cost-effective airplane to operate, while also meeting all current and pending regulations concerning environmental protection and fuel economy. In order to meet these requirements many advanced technologies were used including:

Wide Chord Fan Blades

Composite Blade Materials

Full Authority Digital Engine Control

Annular Dome Combustors

High Bypass Ratios

The three engine families offered on the 777 come from three distinct manufacturers, General Electric (GE90), Pratt & Whitney (PW4000), and Rolls Royce (Trent). Each is as wide in diameter as the fuselage of a Boeing 737 narrow body jet and generates approximately 85,000lbs of thrust on a 777-200. However, each generates the noise level of a 767's 56,000lbs engines, allowing it to meet the FAA's Stage Three noise regulations.

![]()

![]()